Product description

Axial lead benders with rotary disc cutters offer no-tools-required for setups and changeovers. Changeovers and setups are simple and fast thank to the “no tooling required “ for pitch and lead length adjustments. Axial lead formers do not score or damage component leads, nor do they place mechanical stress or axial tension on the components. The machine is modular and it can be manual\motorized, horizontal or vertical bending or just lead trimer .

- Heavy duty construction, full adjustable for lead spacing, lead length. part diameter, and shoulder length.

- Independent rotary disc cutters for longer cutting life.

- Wont score or damage leads or components. Different Models

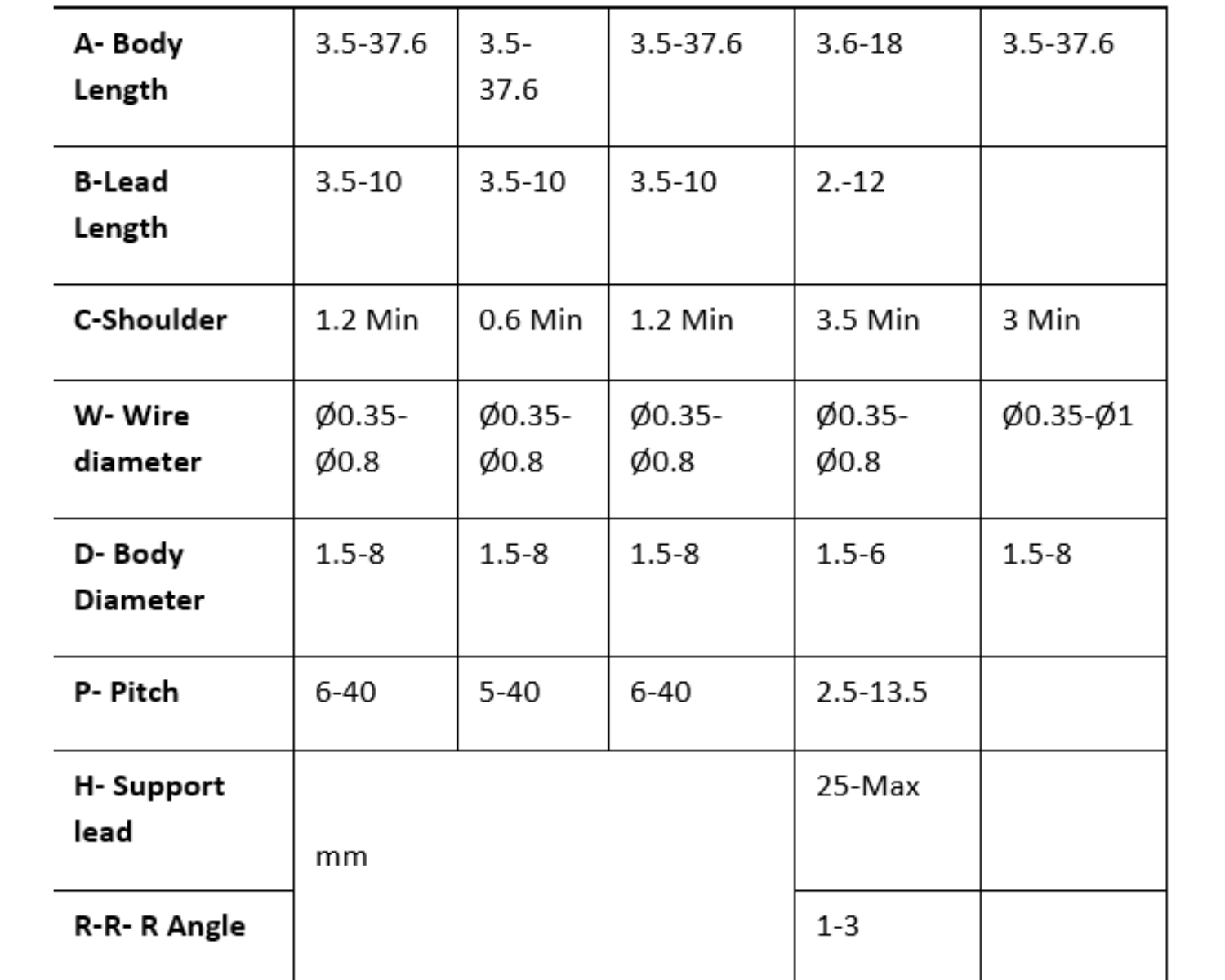

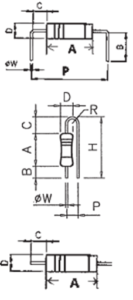

- Standard

- (S) Slim lead for smaller parts.

- (W) Heavy duty- for thicker wire diameter.

- (F) Vertical bending-for stand-up mount

- (L) Linear-Trim off leads at both sides.

Motorized Loose and taped Axial Lead Bender – ASI 8086F ASI PN58123

Dimension:470L x500W x 235H mm

Power: 110V/220V AC. 60/50Hz

Weight: 28kgs

Production Rate: Taped 43,000 pcs/hr

loose 7,200 pcs/hr

Motorized Loose and taped Axial Lead Bender with Bowl Feeder ASI 8090

Dimension:600L x590W x 440H mm

Power: 110V/220V AC. 60/50Hz

Weight: 60kgs

Production Rate: Taped 43,000 pcs/hr

loose 9,000 pcs/hr

Hand-crank Taped Axial Lead Bender ASI 8080

Dimension:380L x180W x 210H mm

Weight: 8kgs

Production Rate: 50,000 pcs/hr

Motorized Taped Axial Lead Bender ASI 8082

Dimension:470L x180W x 235H mm

Power: 110V/220V AC. 60/50Hz

Weight: 15kgs

Production Rate: Taped 60,000 pcs/hr